Basic Info.

Product Description

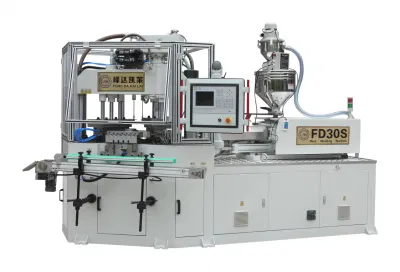

FD30S double servo injection blow molding machine

»Main Features

1.The clamping framework adopts single-crossbeam,double pillars,which enlarges the space of setting mould,will be easier to install mould.

2.Injection clamping adopts the structure of three oil vats and small supply-oil case,hence the speed of open/clamping will be quicker and the bearing pressure of mould will be more equally.

3.using tie-bar protection makes open/clamping mould work while transfer table rise/fall,so the production efficiency improve obviously,and protect core rods damages once mold hasn't at right station.

4.double servo motor system control for 30% consumption saving (Optional).

5.Special thickness working platform with QT material assure machine run stably,clamping well,anti-distortion.

»Operating Principle

Station A:Preform injection

The bottle neck will be molded accurately after injecting the material into the cavity,After proper control,the mold open and mandrils to...along with the cavity.

Station B:Blow molding

Blowing action was done at this part,molding would be complete after cooling.(bottle shape decides by the mold cavity).The air came out from the mandrils huffs the cavity,make the cavity cling to the mold.Then mold open and the mandrils turn to...along with bottles.

Station C:Stripper

The bottle automatically will be ejected from the mandrils at this position and then to be packed.The three actions of injection/blowing/ejection working at the same time,which makes the machine of high efficiency and low waste with bottles.

»Main Technical Parameters

| No. | Item | Unit | FD30 | FD50 | FD70 |

| 1 | Dia. of screw | mm | 40 | 45 | 50 |

| 2 | Screw L/D ratio | 22 | 22 | 22 | |

| 3 | Max. theoretical injection capacity | cm³ | 165 | 254 | 324 |

| 4 | clamping force of injection mould | kn | 300 | 450 | 600 |

| 5 | clamping force of blowing mould | kn | 55 | 70 | 80 |

| 6 | pressure of hydraulic system | Mpa | 14 | 16 | 16 |

| 7 | Max. pressure of compressing air | Mpa | 1 | 1 | 1 |

| 8 | Wastage of cooling water | m³/min | ≥0.3 | ≥0.5 | ≥0.8 |

| 9 | Range of formability product | ml | 1.5-2000 | 1.5-2000 | 1.5-2000 |

| 10 | Height of formability product | mm | ≤200 | ≤200 | ≤200 |

| 11 | Dia of formability product | mm | ≤100 | ≤100 | ≤100 |

| 12 | Total power | kw | 24.7 | 36 | 48 |

| 13 | Overal size(L×W×H) | mm | 3200×1150×2200 | 3750×1300×2300 | 4000×1450×2350 |

| 14 | Machine weight | ton | 4 | 6 | 6 |

»Machine Main Parts Brand

| Key parts | Brand |

| Servo motor / VDP(Optional) | Techmation/Yuken |

| Hydraulic motor | Intermote |

| Hydraulic valve | Yuken |

| Pneumatic valve | Festo |

| Electrical valve | Schendier or Omron |

| Liner scale | JEFFRAM |

| Controller | Jinghua/Omron(optional) |

| Contactor | Schendier |

| Seals | DZ |

| Approach switch | Omron |

»Packaging & Shipping