- Overview

- Product Description

- Product Parameters

- Our Advantages

- Detailed Photos

- Certifications

- FAQ

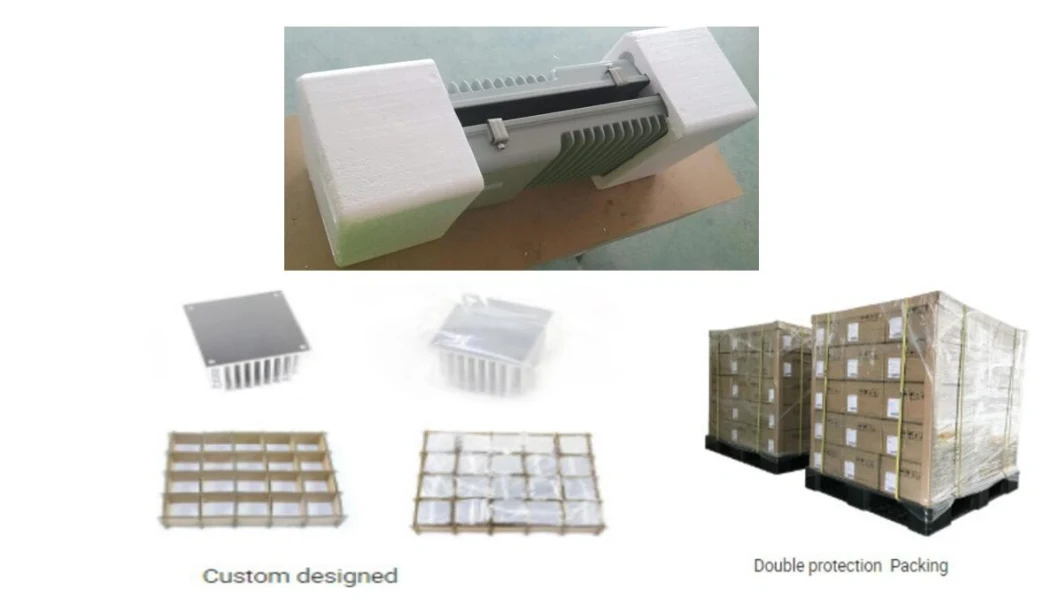

- Packaging & Shipping

Basic Info.

Model NO.

lig-s

Pressure Chamber Structure

Vertical

Tolerance Grade

6

Casting Surface Quality Level

2

Certification

CE, RoHS, ISO 9001:2000, ISO 9001:2008

Finish

Polishing, Deburring, Painting, Sand Blasting

Manufacturer

OEM

Samples

Free

Price

Reasonable

Die Casting Machine

88~1280ton

Mould Life

100000PCS

Capacity

50000PCS/Monthly

Transport Package

Carton Then in Pallet or Per Requirement

Specification

as drawing

Trademark

HFL

Origin

Guangdong, China

HS Code

7616999000

Production Capacity

50000

Product Description

Customized die casting aluminum alloy led steet light by die casting mould

https://hfl-diecasting.en.made-in-china.com/product-list-1.html

Process flowing chart:

Drawing or Sample→Making Mould→Making samples→ casting→Deburriing→Second Machining

Drilling and thread,CNC machining)→Surface treatment(Polising,Anodized,powder

coating,paint,E-blacking)→Assembly and Packing→Shipped→

The inspection will be through each process step.

What kind of die casting we can supply?

| Machine | Die casting machine 88 ton/280 ton/400 ton/500 ton/800 ton/1250 ton | ||||||||

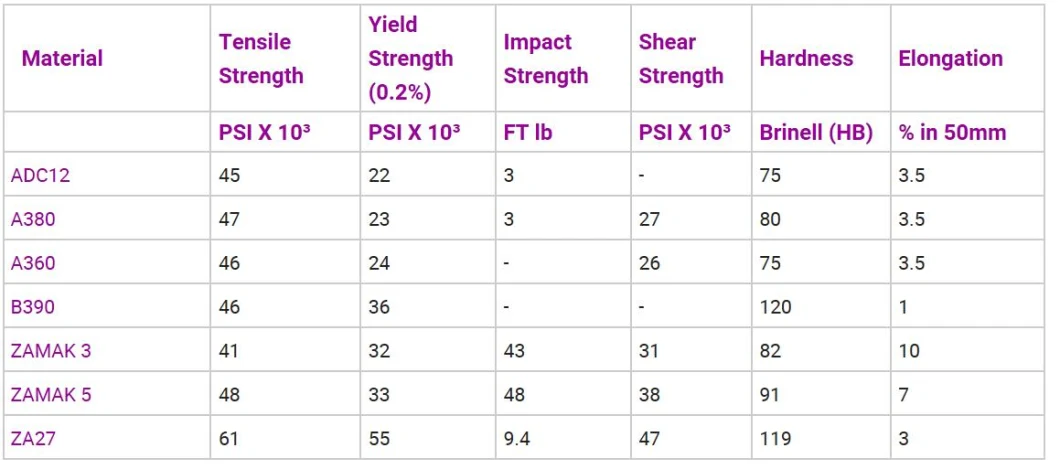

| Material | Aluminum alloy ADC10 . ADC12 . A 360 . A380 .zinc alloy | ||||||||

| Process | Drawing & Samples→Mould making→ Die casting → Deburring → | ||||||||

| Drilling and threading → CNC Machining → Polishing → Surface treatment | |||||||||

| → Assembly → Quality inspection → Packing →Shipping | |||||||||

| Surface treatment | Polishing, Sandblasting, Painting, Powder coating, Galvanizing, Chrome plating,Spray coating, | ||||||||

| Application | Led light housing & Led Heatsink | ||||||||

| Auto & motocyle & bicycle parts | |||||||||

| Furniture accessories | |||||||||

| Power tool housing | |||||||||

| Pump housing | |||||||||

| Mechanical parts | |||||||||

| Diecasting kitchen utensils | |||||||||

| Drawing Format | Auto CAD,CAD, PDF,3D, SLDPRT | ||||||||

| ISO Cetificate | ISO9001-2008, Rohs | ||||||||

| Payment term | T/T, L/C, Western union | ||||||||

| QC system | 100% inspection before package or one by one | ||||||||

| Lead time | 10~25working days according on quantity | ||||||||

| Monthly capacity | 50,000pcs | ||||||||

| Our advantage | More than 15 years of experience in die casting field. | ||||||||

| With talented and experienced engineers | |||||||||

Why you choose us?

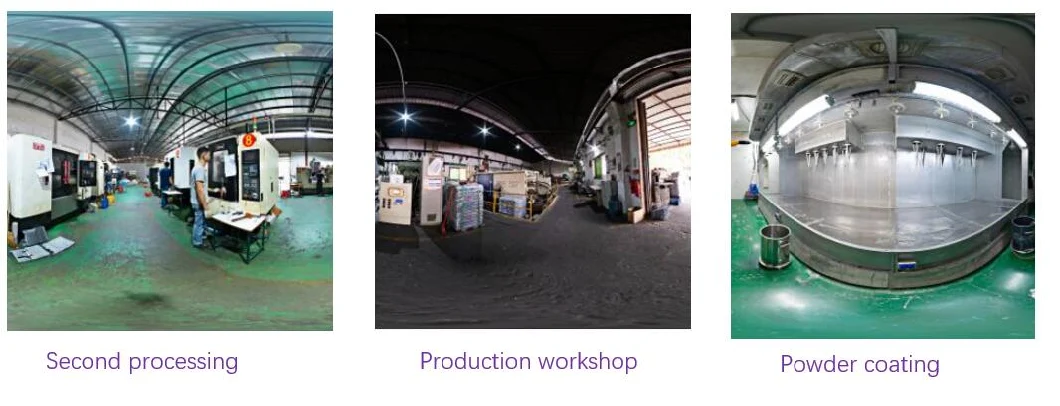

1.we have full automatic equipment (Cold chamber die-casting machine, hot chamber die-casting machine, second machining center, multi-axis drilling machine ....

2.we Can also supply with plated and anodized or chromated finish. Plated finish includes zinc, nickel, chrome, antique copper, antique brass etc.

3. professional R & D team (mold designer, mold programmer, etc.)

4. Experienced quality QC team(100% inspection before shipping and provide full tracking services).

5. the excellent sales department (to provide you with 24 hours of service, High quality and competitive prices and timely delivery) .

6. OEM and ODM services (your ideas we realize, your drawings we produce).

7.We have lots of experience in export, we export to many country, Mainly in America and Europe.

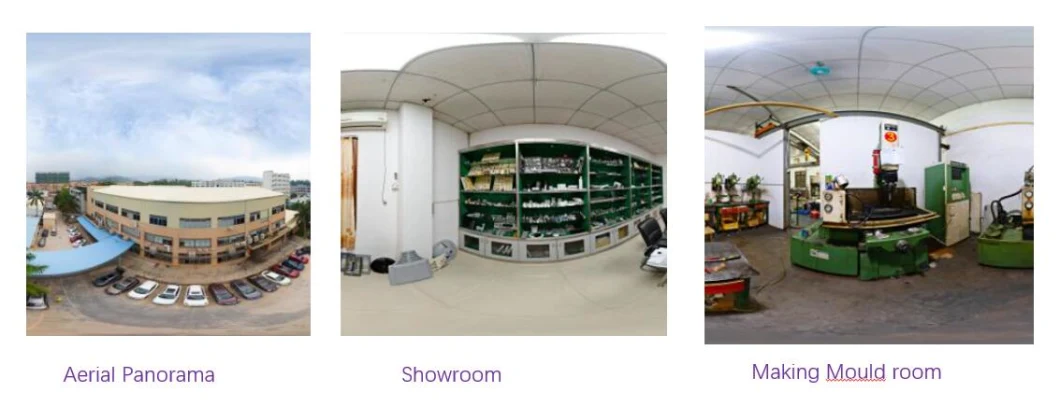

Hong Fu Xin precision technology company founded in 2004 with having ISO9001: 2008 & RoHS certificates. we are specialized in diecasting parts in past 15years. we have full-automatic diecasting machine from 88t to 1250t,4000m2 sand casting workshop, various CNC machining equipment. We are familiar with various surface treatment which have electroplate , Powder coating , anodized , high Polishing , Shot blasting , Sand blasting so on…

What kind products we can do?

. Led light housing & Led Heatsink & led industrial high light

. Auto & motocyle & bicycle parts

.Juice extractor & Coffee machine base

. Furniture accessories & hardware

. Power tool housing

https://hfl-diecasting.en.made-in-china.com/company-Huizhou-Hongfuxin-Precision-Technology-Co-Ltd-.html

FAQ:

1. Are you a manufacturer or a trading company?

We are a professional manufacturer with over 15 years' export experience for designing and producing mult die casting parts.

2. How can I get some samples?

If you need, we are glad to offer you free samples,but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

3. Can you make casting according to our drawing?

Yes, we can make casting according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

4. Can you make casting based on our samples?

Yes, we can make measurement based on your samples to make drawings for tooling making.

5. What's your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of casting.